High-Speed Spindle Leaking Coolant

When a customer noticed their high-speed spindle was noisy and had coolant leaking through the spindle, they called Advanced Spindle Technology to conduct a complete evaluation.

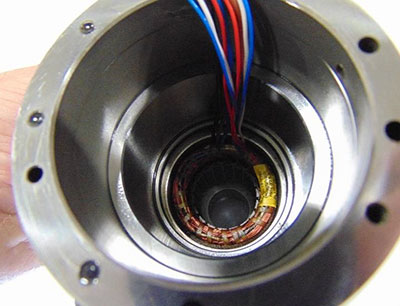

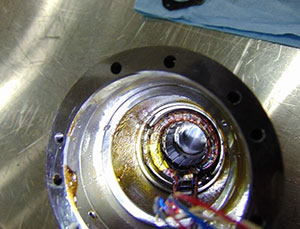

During the disassembly of the GMN HSX 80S high-speed spindle, Advanced Spindle Technology found the coolant jacket around the stator was eroded through. It was clear the coolant jacket needed to be replaced or repaired to get the spindle back into operation. There was also minor contamination found throughout the spindle bearings.

The reasoning behind the faulty spindle was most likely due to normal wear and tear. Spindles are the backbone of machining tools and over time can fail. Having a spindle repair partner like Advanced Spindle Technology that can quickly identify and fix the spindle issues can get your shop back on track – fast!

At the conclusion of the evaluation, a report was supplied to the customer with detailed results and a proposal to get the spindle to “like new” condition. Understanding the work that needs to be completed, the customer instructed AST to repair the spindle.

- Advanced Spindle Technology performed the following work:

- Cleaned and inspected all components

- Replaced all bearings

- Replaced all O-rings and seals

- Replaced motor stator cooling sleeve

Once the work was completed and the spindle reassembled, Advanced Spindle Technology completed a series of tests and system checks to ensure the spindle would operate at top performance.