Key Elements to Proper Spindle Storage

Key Elements for Spindle Storage

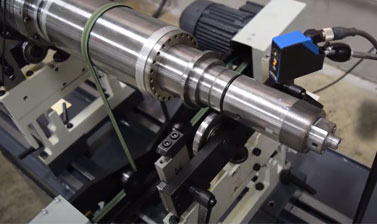

Having a spare spindle on-hand for when your lathe, mill, or grinding machine goes down can save you both time and money. But, what happens if your spindle wasn’t cared for properly while being stored? Spindles can rust and corrode over time, and most likely, your warranty may have expired, OUCH!

When storing your spare spindles follow these best practices:

- Inspect your spindle before placing the spare spindle in storage.

- Store your spindle in a temperature and humidity controlled environment.

- Rotate your spindle 11 revolutions, every-other-week.

- Before utilizing your spindle in production, check for proper functionality.

By following these steps, you can ensure your spindle is being stored correctly.

Depending on your spindle manufacturer or spindle repair specialist, stored spindles may not be covered after the initial term limit from the purchase date. You’ll want to discuss warranty details with your spindle contact to review terms.

Spindle storage is a service that Advaned Spindle Technology offers to our customers. If you would like more information, visit our Spindle SPA page.

View this and all of Advanced Spindle Technology’s video on our YouTube Channel.