Your machine’s tool spindle is the heart of productivity, and any unexpected downtime can have a significant impact on your operations. To ensure a smooth and uninterrupted workflow, it’s crucial to implement a proactive maintenance routine. We’ll delve into six essential tips to prevent your part productivity from coming to an abrupt halt due to a down tool spindle.

- Keep Lubricating Fluids in Check: One of the fundamental aspects of spindle maintenance is to keep lubricating fluids clean and at safe operating levels. Follow the recommended lubrication and/or air-intake filter replacement schedule to ensure optimal performance and longevity of your spindle.

- Monitor Spindle Runout: Checking spindle runout every six months and after any crash is crucial for identifying potential issues. Utilize a ground and calibrated spindle test bar to monitor spindle spring force with a drawbar pull force test. This proactive approach helps you catch problems early on, preventing further damage and ensuring precision in your machining processes.

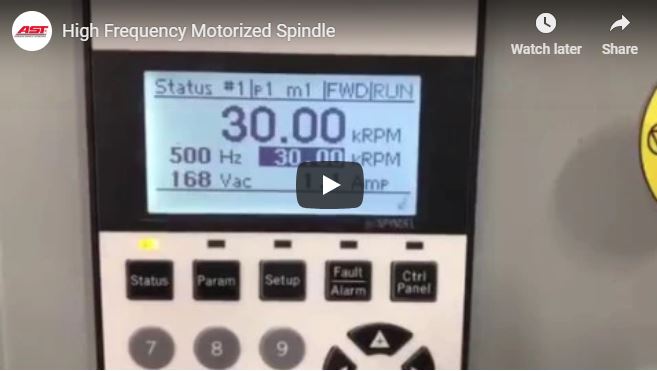

- Closely Monitor Spindle Vibration: Spindle vibration can be an early indicator of problems. Do not ignore triggered alarms from built-in vibration sensing systems. Regularly monitor spindle vibration levels and take immediate action if any irregularities are detected. Timely replacement of worn spindle bearings is essential to maintain the stability and accuracy of your machining operations.

- Maintain Spindle-Bearing Lubrication: For large spindle headstocks that are not factory lubricated for life, it’s crucial to maintain spindle-bearing lubrication. These spindles often require regular lubrication with oil baths. Ensure you follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricants to keep your spindle bearings in optimal condition.

- Check Chiller Units for Spindle Coolant Systems: The efficiency of your spindle coolant system is integral to the overall health of your tool spindle. Regularly check and ensure that chiller units for spindle coolant systems are running properly. Proper cooling prevents overheating, which can lead to premature wear and damage to your spindle components.

- Re-Install Machine Covers: After routine maintenance or for any other reason, always re-install any machine covers that have been removed. This simple step is often overlooked but is crucial in preventing spindle contamination. Contaminants can lead to increased wear and tear and, ultimately, a decrease in the lifespan of your tool spindle.

By incorporating these six maintenance tips into your routine, you can significantly reduce the risk of unexpected downtime and keep your tool spindle running smoothly. A proactive approach to spindle maintenance not only ensures the longevity of your equipment but also contributes to the overall efficiency and productivity of your machining processes.